Showers

![]()

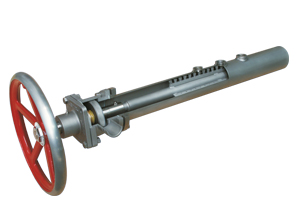

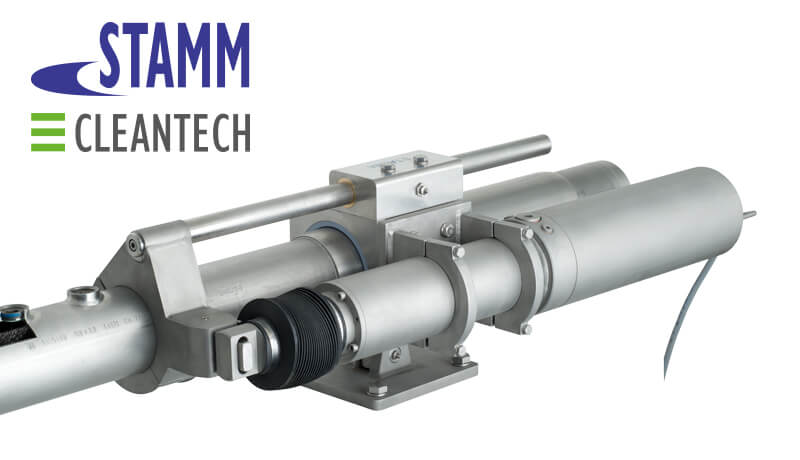

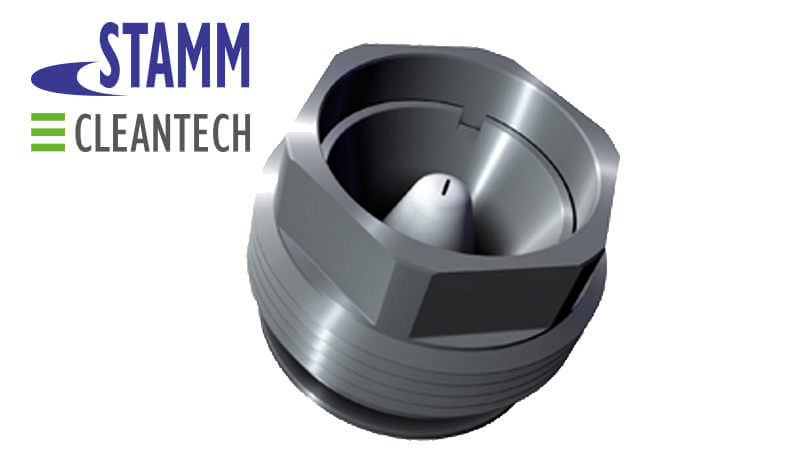

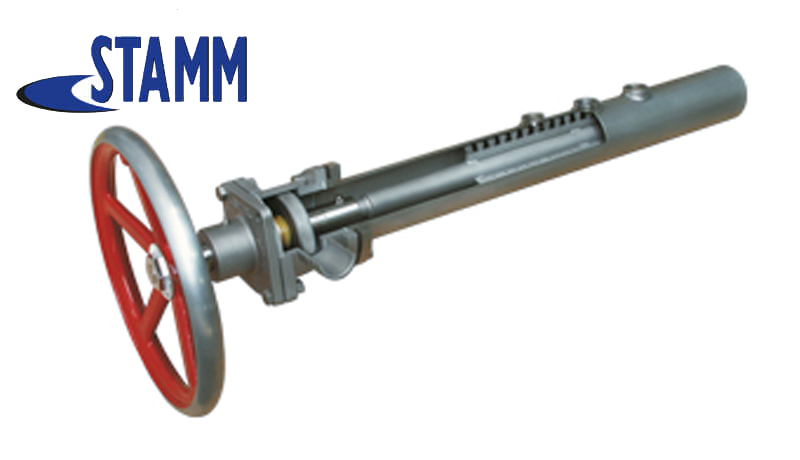

Showers ‣ with manual

Cleaning device ‣ Nozzle-Spray showersProduct Inquiry- Can be used in freshwater, clear-water and backwater applications.

- Considerable freshwater savings and low water consumption.

- Immediate cleaning of the nozzles during operation while removing dirt at the same time.

- Easy operation; just turn the handwheel and the cleaning device moves both axially and radially so that the dirt is removed via the valve which has now opened.

- High nozzle efficiency.

- Easy nozzle removal. The nozzles are made of high molybdenum stainless steel 1.4439 and are available in a variety of sizes and types to suit all shower applications.

- It is easy to alter the type of nozzle (fan-jet and needle-jet) as well as nozzle size.

- Nozzles are firmly attached to the shower.

- Easy adaptation to each shower application.

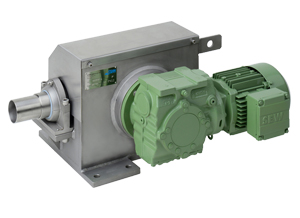

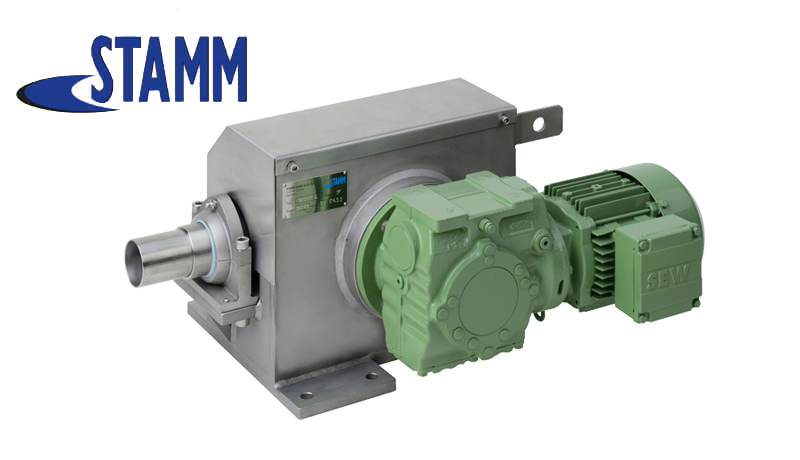

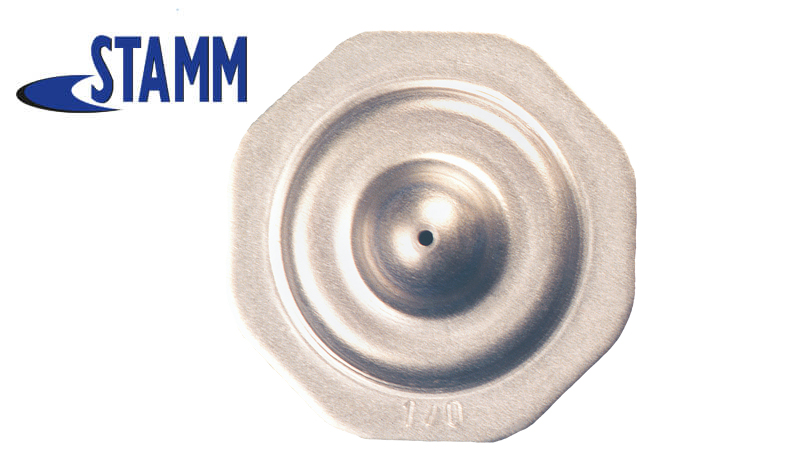

Showers ‣ with manual

Cleaning device ‣ BrushProduct InquiryThe perfect brush for efficient spray-shower cleaning.

Cleaning devices are the simplest and most process-reliable solution, in order to achieve a good spray, even with water contaminated with fibers and suspended solids. The efficiency is largely determined by the choice of the brush.

Whether stainless steel or syntetical bristles, whether welded, screwed or directly pulled in bristles - we will find the perfect solution for you.

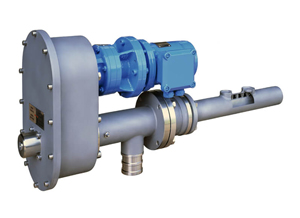

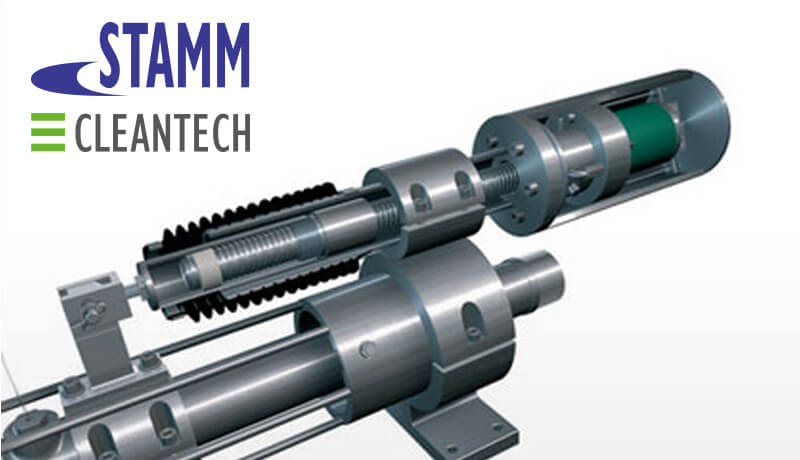

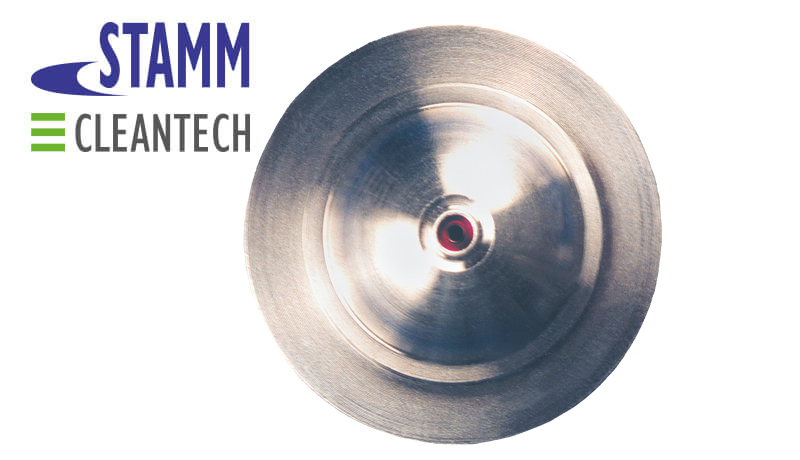

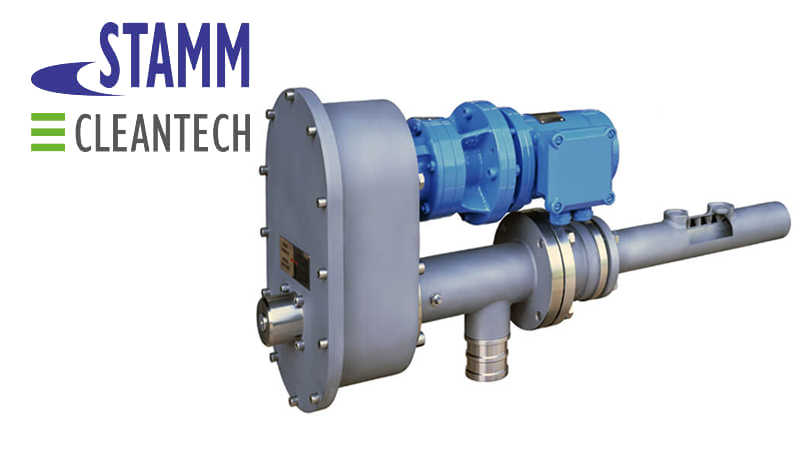

Showers ‣ with automatical

Cleaning device ‣ Valve 10.900Product Inquiry- Regular cleaning of nozzles thanks to automatic operation of the cleaning device

- Celaning cycle ("open valve", "rinse shower", "close valve") at freely programmable intervals

- Firm closure of valve with a defined closing force

- Existing showers can be retrofitted with this device

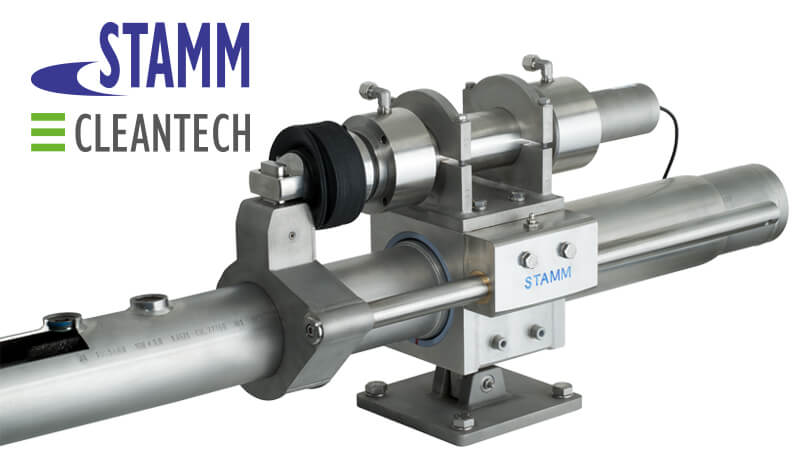

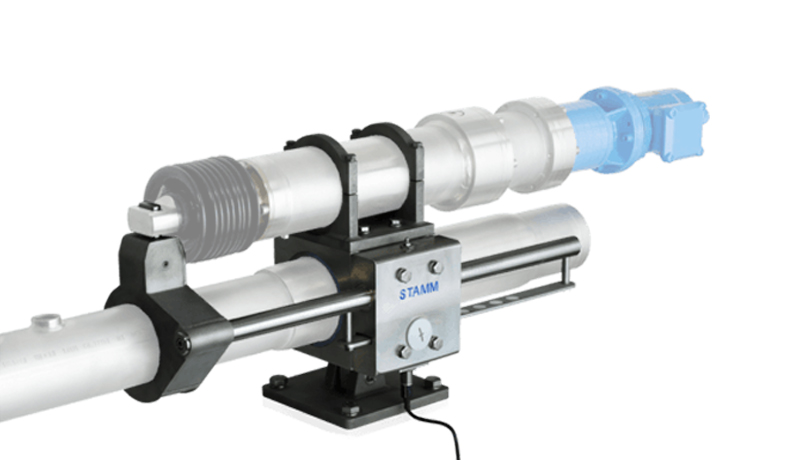

Showers ‣ without

Cleaning device ‣ Tailor-made showersProduct InquiryA cleaning device is not always mandatory or even possible. We also help you solve complex problems.